When it comes to screening and filtering materials in various industries, strength and versatility are key factors for success. Custom woven wire mesh has become a popular choice because it offers these qualities in an effective and reliable way. This article explores how custom woven wire mesh stands out as a superior option in screening solutions.

Understanding Custom Woven Wire Mesh

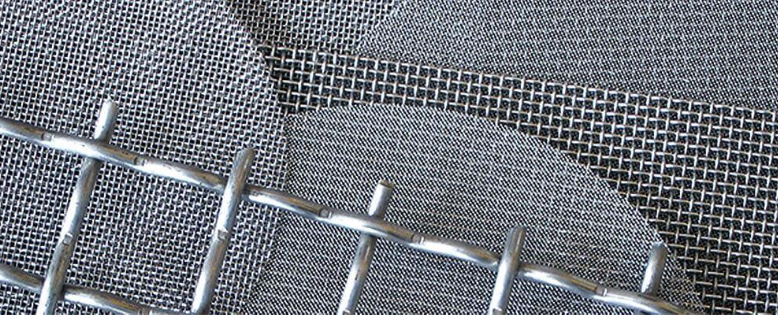

Custom woven wire mesh is made weaving wires together in a specific pattern to create a strong and flexible sheet of metal. The wires can be made from different materials, such as stainless steel, galvanized steel, or other metals, depending on the needs of the user. The weaving process can be adjusted to create meshes of various sizes, thicknesses, and strengths, allowing for customization that fits specific tasks.

The ability to customize woven wire mesh means that it can be tailored to handle different screening challenges, whether it’s for filtering fine particles or holding back larger materials. This makes it a highly versatile product suitable for many industries.

Superior Strength of Custom Woven Wire Mesh

One of the biggest advantages of custom Woven Wire mesh is its superior strength. The weaving process creates a structure where wires support each other, giving the mesh a strong, stable form. This strength makes it resistant to tearing, stretching, and breaking, which is important for long-term use in demanding environments.

Additionally, the choice of wire material adds to the strength. For example, stainless steel wires are highly durable and resist corrosion, making the mesh ideal for outdoor or harsh chemical environments. The strength of custom woven wire mesh ensures that it can withstand heavy loads and impacts without losing its shape or effectiveness.

Versatility in Screening Solutions

Custom woven wire mesh is not only strong but also very versatile. The mesh can be designed to have different opening sizes, wire thicknesses, and weave patterns. This flexibility allows it to be used in a wide range of screening applications.

For example, in the mining industry, the mesh can be made with large openings to separate big rocks from finer materials. In contrast, in the food processing industry, it can be woven with very fine openings to filter out tiny particles or impurities. This versatility makes custom woven wire mesh a valuable solution for many sectors, including agriculture, construction, chemical processing, and water treatment.

Customization Meets Specific Needs

The ability to customize woven wire mesh means it can be perfectly matched to a customer’s requirements. Whether the need is for corrosion resistance, heat tolerance, or specific mesh sizes, custom woven wire mesh can be manufactured to meet those exact standards.

Manufacturers work closely with customers to understand the application and recommend the best wire type, weave pattern, and mesh size. This close collaboration helps ensure the mesh performs well and lasts longer in its intended use.

Benefits Beyond Strength and Versatility

Besides strength and versatility, custom woven wire mesh offers other important benefits. Its open structure allows air, light, and fluids to pass through while blocking unwanted materials. This makes it excellent for ventilation, filtration, and safety guards.

Moreover, woven wire mesh is easy to clean and maintain, which is especially important in industries like food processing or pharmaceuticals, where hygiene is crucial. Its durability also reduces the need for frequent replacements, saving time and money in the long run.

Conclusion

In summary, custom woven wire mesh provides superior strength and unmatched versatility for screening solutions across many industries. Its durable construction, combined with the ability to customize every aspect, makes it an ideal choice for filtering, separating, and protecting materials.

Whether you need a tough mesh for heavy-duty mining or a fine filter for delicate food products, custom woven wire mesh can be tailored to fit the job perfectly. Choosing this type of mesh ensures a reliable, long-lasting solution that meets your specific screening needs with confidence.